However, There is certainly one thing to bear in mind. This desk applies to design steels by using a yield energy of all around 400 MPa.

The back gauge is usually a Doing work part that controls The placement on the bending line, when the higher and decrease molds are applied to regulate the bending angle and inner radius with the workpiece. Whether or not the workpiece is qualified or not is mainly determined by these a few pieces.

Air bending entails deforming a metal sheet by making use of drive with out totally bottoming out the punch into the die. Through the air bending approach, the punch pushes the sheet metal to the die cavity, but it does not come into connection with the bottom from the die. This hole among the punch and also the die will allow additional versatility and control about the bending angle.

Essentially, the k factor offsets the neutral line to deliver a flat pattern that demonstrates fact. Through the use of it, you will get the bend allowance which can be, in essence, the length in the curved neutral axis.

Price Report, the common return on investment decision for metal roof replacement is all over sixty one.2%. Homeowners can recoup much more than 50 percent of their roof alternative costs if they provide their residences.

Copper is commonly useful for attractive programs but is additionally an excellent conductor and corrosion-resistant.

Tilcor's™ CF Shingle is specially built to resemble the look of standard Asphalt Shingles but without the inherent ongoing concerns that a lot of house owners facial area.

Air bending—also called partial bending—is just not as correct as coining or bottoming. Air bending is typically employed when a less complicated Option is necessary as it doesn’t require using tools. One of many key downsides to air bending is always that springback can manifest.

Furthermore, for an excellent bend the return duration needs to be 4 moments the sheet metal thickness. Likewise, teardrop hems need to even have an inside of diameter that is equal towards the sheet metal thickness in a minimum. Additionally, the opening must be at the very least 25% from the sheet metal thickness as well as operate duration has to be no less than 4 periods the sheet metal thickness subsequent the radius.

Choose from among the obtainable grades beneath to get going. Or Make contact with your closest keep for support with metal sourcing.

Bottoming is often called bottom pressing or base putting. As the name “bottom pressing” indicates, the punch presses the metal sheet on to the floor of your die, so the die’s angle determines the ultimate angle of your workpiece. With bottoming, the interior radius of the website angled sheet is determined by the die’s radius.

When bending transverse towards the grain way, the lessened ductility will boost the demanded forming tonnage, but Will probably be effective at accepting a Substantially tighter within bend radius without having destroying the surface area on the bend.

If asked for, we can also weld up the corner to provide a sealed seam. Avoid placing holes far too near the bend. Find them at the least 4x the fabric thickness faraway from any edges or within corners.

(mm) that is necessary for such specs. Just about every operation wants a particular tonnage for every meter. This really is also proven from the desk. You'll be able to see that thicker elements and smaller inside radii demand additional pressure or tonnage. The highlighted alternatives are suggested technical specs for metal bending.

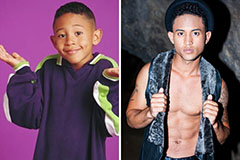

Tahj Mowry Then & Now!

Tahj Mowry Then & Now! Melissa Joan Hart Then & Now!

Melissa Joan Hart Then & Now! Shane West Then & Now!

Shane West Then & Now! Freddie Prinze Jr. Then & Now!

Freddie Prinze Jr. Then & Now! Peter Billingsley Then & Now!

Peter Billingsley Then & Now!